|

|

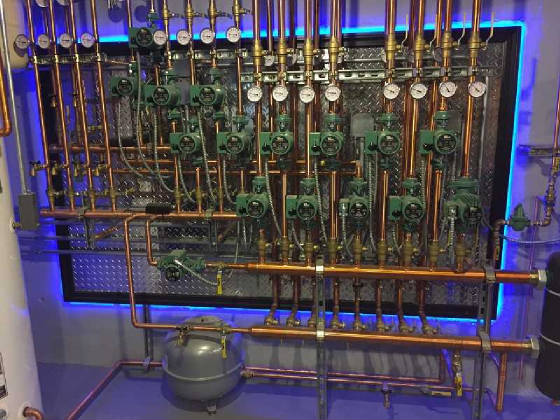

"Oil fired Hot Water System" converted to

dual "Lochinvar

Modulating-Condensating Gas Boilers". [Click on pictures to enlarge]

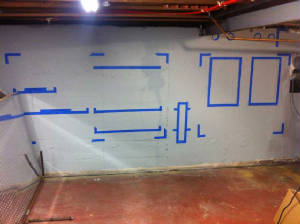

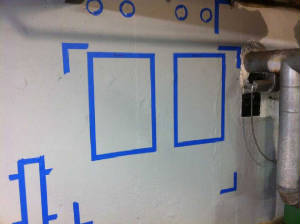

Careful planing and a lot of future

thought went into the developement and design of this complete heating system. With future plans of a major expansion down the road, this system was designed to provide all the heating requirements that will be needed. Provisions for radiant heating,

second stage back up hydro air coils, garage space heaters, future pool heating and snow melt systems were all incorporated into the build of this boiler room. Literally, this is a "Plug

and Play" system that will enable

this house to morph into its final configuration. The choice of dual Mod-Con

bolers was elected for two reasons: #1 - To provide the most efficient means of supplying

heat upon demand. One boiler will handle the majority of low-demand requirements, which is most of the time. Upon high demand requirements, the second boiler will kick in and provide

the extra btu's to get the job done.

The Tekmar Universal Reset module rotates the running time of both boilers to share the work load and wear and tear. #2- Having two boilers provides redundancy in the case of a boiler failure. If one boiler drops off line due to boiler

failure, the other will kick in to keep

things going. A Generac natural gas generator was also installed to provide redundancy for whole house electrical power back

up. Home automation was tied in using

the Tekmar 482 Gateway control to provide iPhone monitoring and system control. The system is fully operational and ready to go. All that has to be done is run the final

piping and wiring down to the boiler room and literally "Plug and Play". This is the way all

installations should be designed and built. And yes, those are remote controlled RGB LED lights around the system boards and behind the Tekmar controls. |

Enter supporting content here